Specialized in precision casting of gold and platinum group metals , we support our customers from the first sketch of the creative production of the finished jewel.

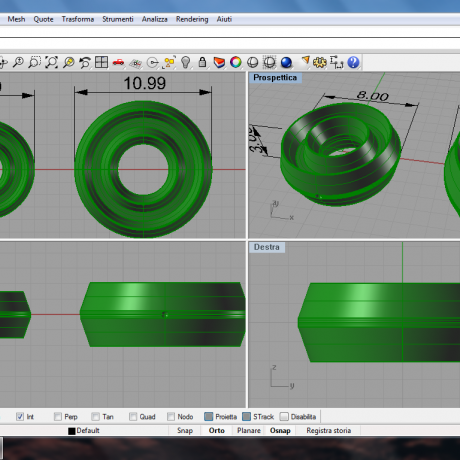

PROJECT WORK

Starting with an idea we switch to the sketch, to a technical drawing, and we finally develop the object in wax by hand, or in 3d.

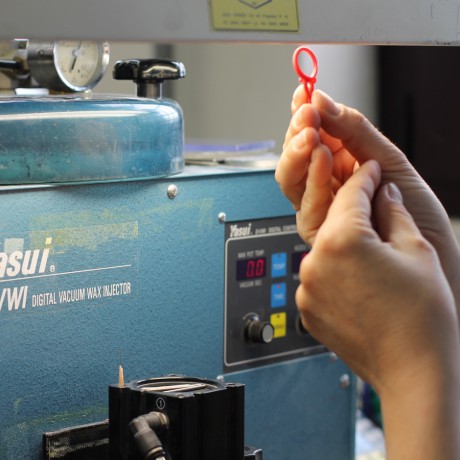

WAX-PATTERN STAGE

By using silicone rubber molds, we produce the waxes of the objects.

CASTING

Through induction machines, we obtain the desired object in various precious metals (Gold, Platinum, Silver, Palladium).

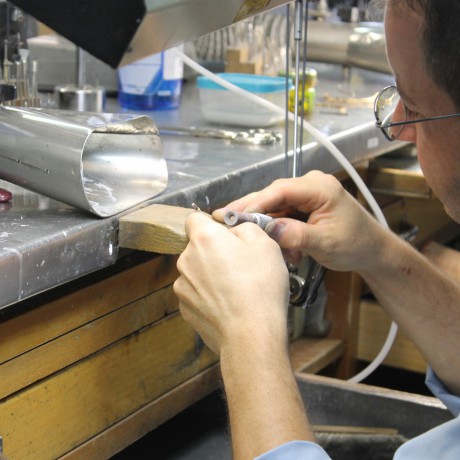

HANDMADE STAGE

With the acquired technics and knowledge, expert goldsmiths begin the process of manual processing till the finished jewel.

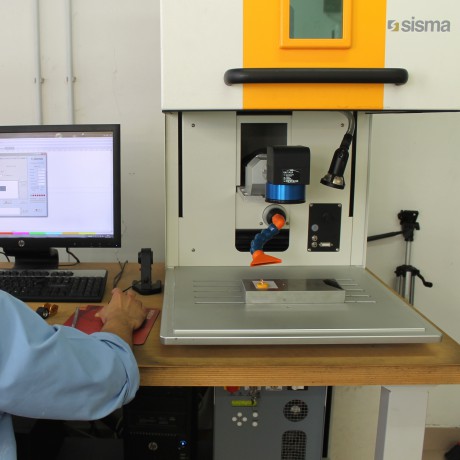

LASER ENGRAVING

With the laser technology we can engrave the jewel with the any desired writing or pattern.

STONE SETTING

It allows us to embellish with gems and diamond the jewelry that takes shape.

FINISHING

This phase aims to polish the objects to make them shine.

RHODIUM PLATING

By means of a galvanic bath, jewels are coated with a layer of rhodium in white gold, to make it get the characteristic color.

QUALITY CONTROL

The visual inspection, by means of precision tools, is done on every single item, to ensure conformity of quality.